Advanced nut plate machine build part 1

We make these, our current nut plates:

With this, our venerable 20 year old CNC:

Poor old thing is starting to fall behind, now’s the time to build a dedicated machine to make these (hand drilled prototype shown):

Out of this, our new extruded nut plate material:

Over the next few weeks, my intention is to illustrate our project to build a nut plate making machine. There a hand full of “firsts” for us in this machine build: the first Arduino control, first Arduino programming, first synchronized tapping with stepper motors, etc.

This project is “build as we go”, in that we have a general outline as to how we are going to meet our requirements, but we don’t have the time or resources to get all our ducks in a row before building. At completion, we will have sufficient documentation to build another one, make spares, have operation instructions, show you how we made it, and the like.

The next photo is our last house built production machine for Microrax, an automatic cut off saw. It uses an USB barcode reader to enter the length to cut from empty bins. This machine uses an industrial stepper motor controller to run the entire machine. The programming language is old and esoteric, so we are happily entering the Arduino realm.

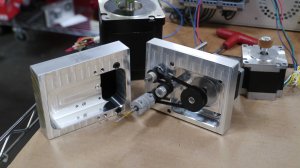

The following photos are what we have to this point, the three stepper motors for stock feed, drill platform, tapping motor (gearbox opened up to show belt drive to two spindles), and the control box (repurposed from a cheap chinese desktop CNC):

Part 2 will be a review of requirements and some design work. If you have any questions, please comment, I’ll make every effort to respond.

Cheers,

Steve